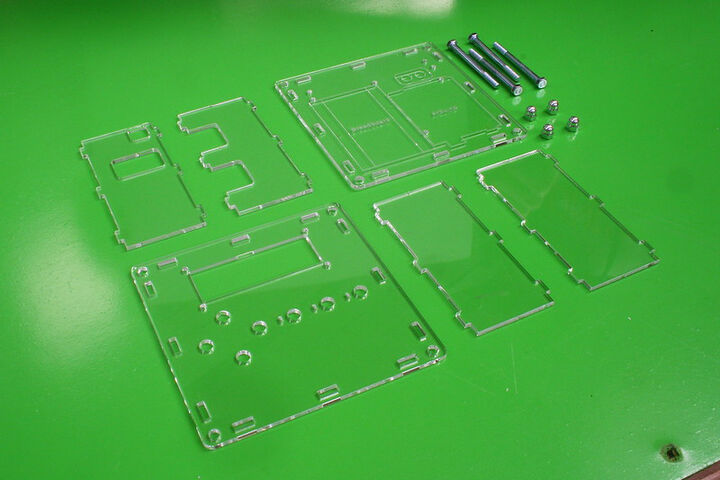

PMMA (polymethyl methacrylate), known as Acrylic is a versatile plastic material, quite popular in laser cutting and engraving specifically. While mechanical stiffness and temperature resistance of acrylic may be lacking, its attractive surface, easy formability, and affordable cost along with a huge variety of available colors and patterns add benefits to the material. It is used widely in the signage and award industry, however, acrylic is also used for boxes, cases, and even 3D printer frames.

Order in Acrylic

| Property | Value |

|---|---|

| Relative Density | 1.19 g/cm³ |

| Light Transmission | >92 % |

| Tensile Strength at yield | 75 MPa |

| Elongation at break | 4% |

| Flexural Modulus | 3210 MPa |

| Softening Temperature | 110 °C |

Acrylic, also known as Plexiglass, is a thermoplastic called PMMA or polymethyl methacrylate. Raw acrylic exhibits a high level of clarity and transparency, making it useful as a glass substitute.

There are 2 main types of acrylic, which should be selected depending on the cutting process:

Acrylic material is easy to laser cut to good results and flame-polished edges. Laser engraving of acrylic also delivers good results. It is critical to select a suitable type of acrylic for a particular manufacturing process to achieve the best possible quality.

Acrylic can be CNC machined on routers, turning, and milling centers. Machined acrylic parts are used for tanks, panels, and optical applications. It is suggested to avoid thin walls and details smaller than 0.5 mm for CNC milling of PMMA sheets as well as complicated geometries. Compared to laser cutting, milled acrylic may require post-processing to bring back optical clarity and give a better finish to the edges.

Acrylic sheets are relatively easy to cut on CNC routers, mills, turning machines, and laser cutters.

Acrylic sheets are a type of plastic, more precisely a thermoplastic. Acrylic properties differ from other plastics naturally. For example, it exhibits less strength than polycarbonate as well as lower stress resistance. But on the upper side, acrylic is more resistant to scratches and provides better stiffness and surface appearance.

Acrylic (also known as Plexiglass, acrylic glass) is flammable. It also has a relatively low continuous service temperature.

Acrylic is not completely scratch proof. While machined or transported it is covered with a protective film to avoid scratches. However, in comparison to some other plastics, like PC, acrylic exhibits better resistance to scratches.

All Comments (0)