Lasers are used in many industries to treat people, detect motion and manufacture products. Computer-controlled (CNC) laser cutting, marking and engraving machines are a convenient way to create industrial and custom consumer products like signs, badges, gears, tags, e t.c. There are various CNC laser-based machines that allow running different types of tasks depending on a specific application.

- What is CNC laser cutting?

- What is Laser engraving?

- How does Laser Cutting machine work?

- What types of lasers are there?

- Advantages of CNC laser cutting machines

- What are the most popular products to laser engrave?

- Disadvantages of CNC laser cutting machines

- What is the difference between CNC milling and Laser Cutting?

- What are the advantages of CNC laser cutting services?

What is CNC laser cutting?

Laser Cutting is a process of manufacturing parts by directing a laser beam onto the material to cut out a specific geometry. The laser is focused on a spot with the help of optics and computer code to melt or burn out the exes material.

What is Laser Engraving?

Laser Engraving and laser marking are relatively similar processes - the difference is that they will just remove a top layer (or a few) of material to leave the details on the surface.

Lasers can also engrave the color into a material. Usually, the process is referred to as laser marking, which allows oxidizing the material until it changes the color to a specific one. By controlling the length of a laser wave and speed, material type and surface finish, many colors can be achieved.

There are some alternative laser marking methods as well: these include creating a cavity on the acrylics, putting a dye and engraving the surface again with lower power and higher speed to melt the dye into a workpiece.

How does Laser Cutting machine work?

The laser cutting process can be described as melting because what the laser beam does is melts or evaporates the extra material, which you don’t need on the workpiece.

Laser cutting process step-by-step:

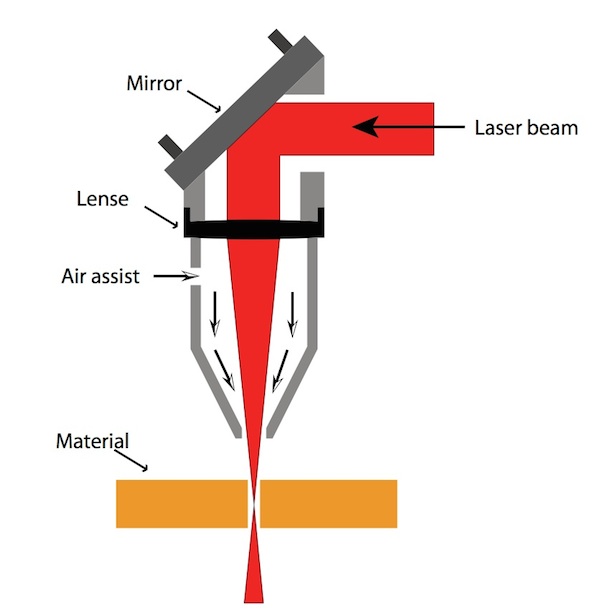

- The laser beam is generated.

- Mirrors or beam benders direct it through the nozzle.

- Special lense in the cutting head focuses the laser beam in one spot.

- Material is evaporated from this focus spot.

Image by Artisan Model Makers

In order to get different types of results or work on specific materials, laser cutters should meet power, heat output, intensity and wavelength parameters. Delicate materials such as fabric, leather or paper are cut with less powerful lasers to avoid overheating. On the contrary, tough workpieces i.e. gemstones, metals and thick objects require high power cutters.

What types of lasers are there?

- CO2 laser

- Nd: YAG Laser

- Fiberglass laser

The CO2 laser is one of the most common types used in cutters. It operates through an electrically stimulated dioxide mixture. Modern CO2 lasers use radiofrequency energy instead of the electrodes. The older versions weren’t completely risk-free since the electrodes inside a cavity could face an electrode erosion.

Nd: YAG Lasers use crystals and laser diodes or flashlamps to pump the beams, which results in large cutting capabilities. Therefore, these crystal lasers are commonly used in welding, industrial-grade cutting, and manufacturing.

Fiberglass laser uses a "seed laser" that is amplified by glass fibers and diodes. This type is much stronger compared to CO2, and it can be used on both metal and non-metal materials.

What is the advantage of a CNC laser cutting machine?

Laser cutters are considered more precise compared to mechanical mills. Additionally, they deliver nice, smooth and sealed edges of parts, which allows skipping some post-processing.

Image by: Steve Rainwater

- Lasers are generally better in rounded shapes compared to mechanical tools that have more geometrical limitations.

- Speed is another huge advantage of a laser cutter. The laser is able to cut thick materials in one run, while other cutters may require several passes.

- Fewer consumables and replacements. There is no need to buy various tools and change them to proceed with different cuts as there are no bits to wear. Some owners mention they also save money by eliminating material preparation and edges post-processing.

- Non-contact process. Laser cutter doesn’t interfere with a material piece with any tools. Sometimes even fixing a work table isn’t necessary. This means fewer deformation of an object during the manufacturing process and reduces contamination, which is a huge advantage when part’s appearance is important.

- One tool for multiple applications and materials. A laser can take different forms on the material without a need to change bits.

What are the most popular products to laser engrave?

Laser engraving is used widely for automotive, tooling, electronics, medical, military, aerospace, oil & gas and much more. In these industries, laser engraving and marking are widely used on a daily basis. Speaking of certain end-use and consumer products, laser engraving is a popular method of customizing existing goods and creating low-volume collections by amateur designers.

- Awards and trophies

- Personal gifts and memorabilia

- Decorations

- Nametags, pet collars and IDs

- Signage

- Installations, displays and decorations

- Jewelry

- Pins

- Rubber Stamps

- Wedding Invitations

- Wooden cutting boards

- Leather wallets

- Pillows

What are some disadvantages of laser cutting?

- They “eat” a significant amount of electricity.

- Pricey replacement parts.

- Potential gas release during cutting plastic.

- Powerful laser cutters are very expensive.

- Reflective, brittle or transparent materials (like copper, aluminum, glass) can’t be cut with any laser cutter.

- Burnt or discolored edges can be minimized but they are inevitable, especially on materials like wood, fabrics, paper.

What is the difference between CNC milling and Laser Cutting?

Both CNC milling and laser cutting are widely used methods of subtractive manufacturing. They can partially replace each other but there are particular situations in which one of the technologies is more preferable.

Parts’ Quality

Lasers deliver less post-processing on edges compared to mechanical mills. Usually, it’s a uniform cut around the whole product despite the intricacy of some areas. Burrs, discoloration and small deformity can still occur in the process depending on the material and laser type but the average results tend to be much smoother compared to a mill. With no direct contact between tool and material, laser cutting avoids accidental contamination.

A laser beam is generally more precise and provides a smaller possible radius. Finally, CNC mills put pressure and heat on the workpiece during the process, which can cause cracks and warping.

However, lasers aren’t ultimately better than mechanical mills. They lose in terms of making square shapes and are worse in working with aluminum (compared to CNC punching).

Production Capabilities

Compared to mechanical CNC, laser cutter makes parts quicker with a few exceptions like large batches of simple shapes which are quicker to make via punching or CNC routing. Aside from cutting being quicker, the whole manufacturing process takes less time with less post-processing and preparation.

Geometry and Material capabilities

Some CNC milling machines are capable of making 3D geometries, while laser cutters are tied to 2D format only. In order to determine a range of materials any specific cutter can allow processing you want to look at RPM capabilities and bits for mechanical CNCs and laser type and power for laser cutters.

On average, laser cutters are limited in terms of materials they can handle. Many laser cutters are unable to work with crystals, glass, aluminum, copper and some other materials that are too brittle, transparent or light reflective. Machines that enable cutting crystals or glass are present on the market but commonly very expensive.

What are the advantages of CNC laser cutting services?

Some desktop laser cutters are very affordable and small enough to fit on a table. However, they may be limited to working with softer material and would still require skills and experience. For small batch production applying to a third-party, laser cutting service is a fine solution compared to acquiring a machine for your own.

See our TOP picks for home cutters

- No health risks associated with in-home laser cutting of plastics;

- No need for special qualifications to work with a laser cutter;

- Versatility in changing vendors to cut different materials and sizes;

- No need to prepare vector files yourself as some on-demand services accept other types of files.

In case you find that purchasing a desktop laser cutting machine will be more profitable, check out our rundown on the best desktop laser engravers and cutters.